CNC Ported Heads are they worth HP?

“I’ve got CNC ported heads on my car” you hear this all the time right?

The real questions that needs to be asked is how much power did they gain you?

Who ported them?

What gains did you see on the flow bench vs stock to gauge potential HP gains?

Just because you got the heads “ported” doesn’t mean they are now better….they could be the same or even worse than stock.

This tech article relates to this cylinder head shootout we completed before here: https://fiinterchillers.com/lsa-ls3-cylinder-head-shoot-out/

Here are the excuses you are going to hear from a bad head porter:

1. We don’t race flow benches

2. They don’t know what they are talking about

3. That’s not how it works

4. We have 5-10 different port designs for the LS3/LSA cylinder head

Now here is the truth to those 4 excuses:

1. No we don’t race flow benches however when we compare 1 type of cylinder head to the exact same type of cylinder head we are comparing 3 red apples all picked from the same tree. We are not comparing LS1 to LS3 or LS7. In fact we are actually comparing 1 factory stock LSA head to a 2nd ported LSA head then to a 3rd ported LSA head, all 3 being stock castings.

2. Flow bench data doesn’t lie, you can fudge the dyno all day long, but the flow bench is a very useful tool to gauge gains and losses

3. Same answer as number 2

4. This needs to be in bold – This is by far the most idiotic statement to come out of a head porters mouth specifically when the heads being ported are a factory casting, for a hydraulic camshaft, where 99.99999999999% of people run a lift range of 0.500″ to 0.650″.

Why you may ask, isn’t it a great achievement to have 5-10 different port designs for the 1 cylinder head?

The answer is plain and simple NO! If nearly all of your customer base are running a lift range of 0.500″ to 0.650″ of lift then you make the best damn head possible for that lift range, if for some strange reason someone is running 0.750″-0.850″ with a solid roller and for some also very strange reason they want to be running that much lift on a stock LS3/LSA casting then sure have a different port program for that 1 customer.

Lets go deeper on this, lets say you are a turbo car and you say please head porter please do your best efforts to make the exhaust work really really well so I can come on to boost quicker…..if you achieve this in your port work that just became the exhaust port you now use on everyone’s LS3/LSA head.

Lets go another round, you are an NA car, please head porter please make the intake flow as best you can up to 0.650″ lift that’s my maximum lift range of my hydraulic camshaft and I’ve got a big race coming up and I have to win. Again if you find the port design, that flows the best CFM and velocity again that becomes the standard and out the window goes 5-10 different head port designs for the exact same FACTORY cast head! Remember we are porting stock heads here, this isn’t an alcohol engine running 0.900″ lift on an aftermarket billet head.

Now lets start the education and understand how this works:

When you look at cylinder heads stop looking at peak flow numbers, yes they do matter, but they are no where near as critical as your low to mid lift numbers. If you’ve ever looked at a camshaft lobe you will soon see why. You are at peak valve lift for a very very very short period of time, critical flow figures on your typical hydraulic roller camshaft found on the LSA engine is from about 0.050″ to 0.500″ lift, from 0.550″ to 0.650″ this happens so fast and so briefly these flow figures do matter but are no where near as important as low to mid lift. Especially when you think about it in this aspect: Your intake and exhaust valve have to go from closed to completely open back to completely closed again, passing your low and mid lift area twice!

Typical camshaft lobe, as can be seen you wont hang at peak valve lift for very long

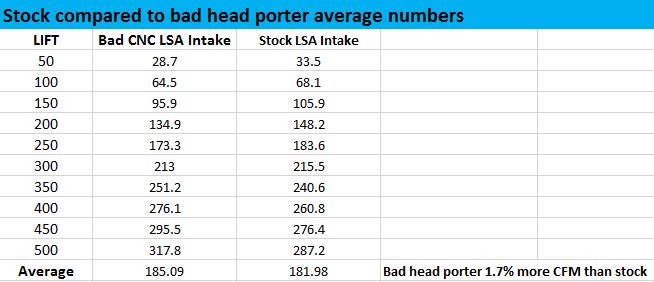

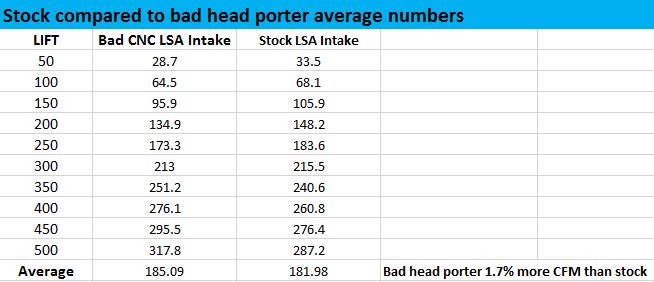

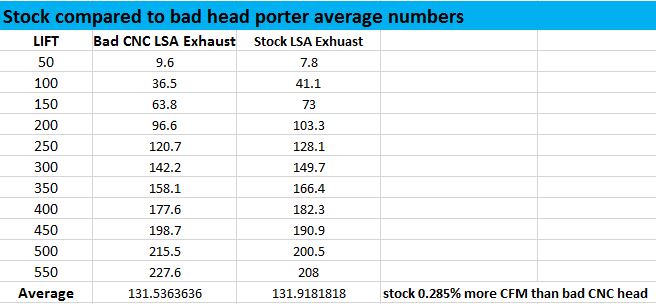

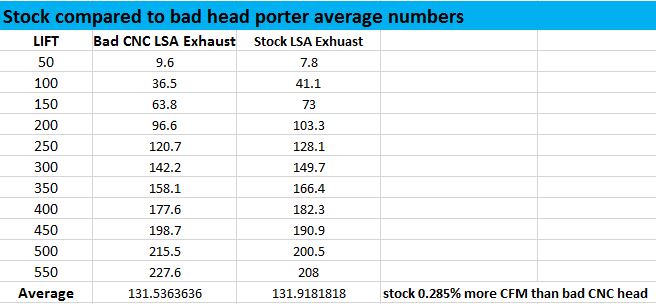

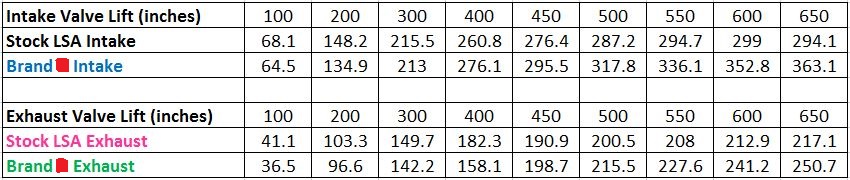

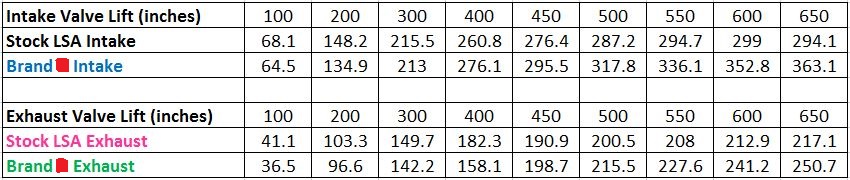

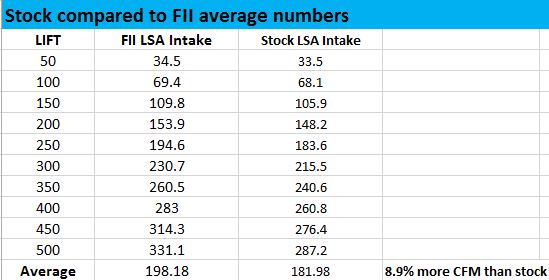

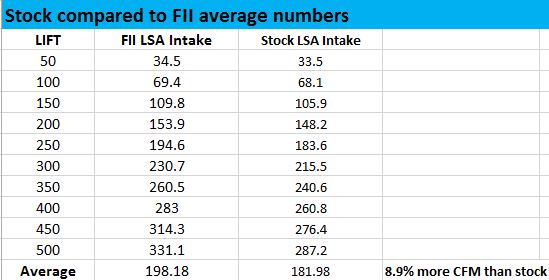

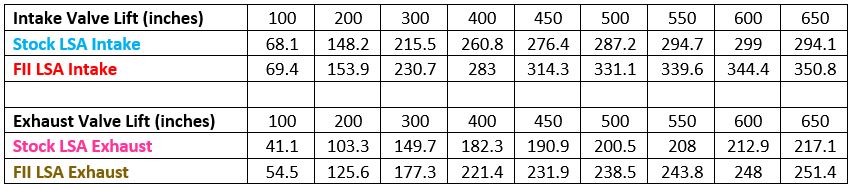

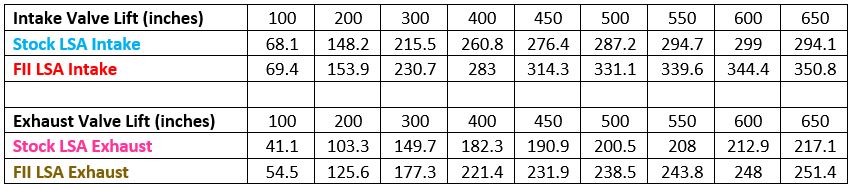

Here we have CFM break points, average CFM at the bottom and the percentage gain from a bad CNC LSA head:

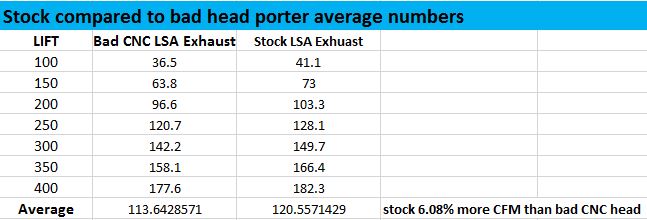

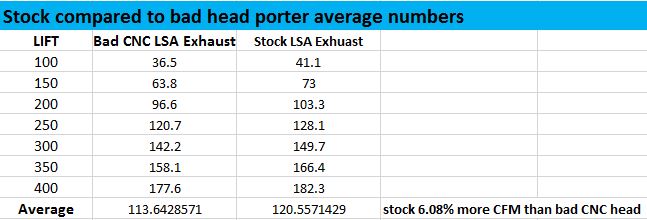

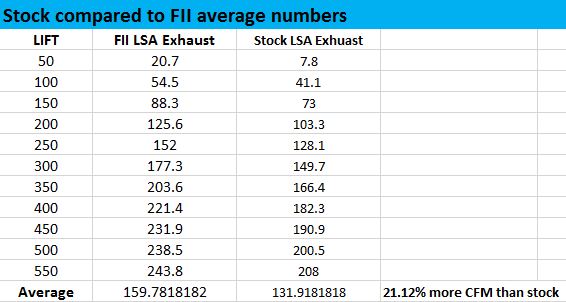

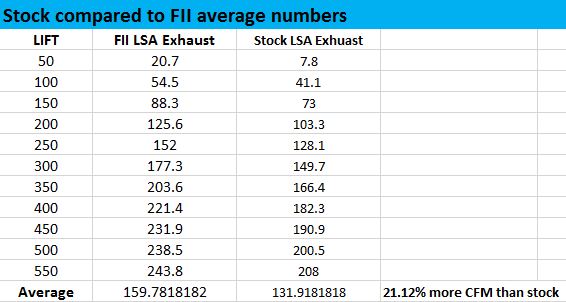

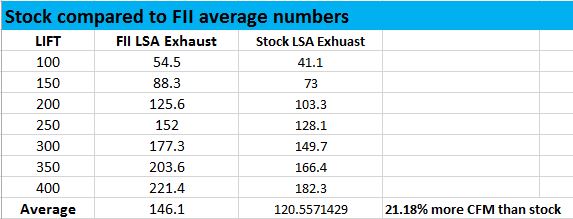

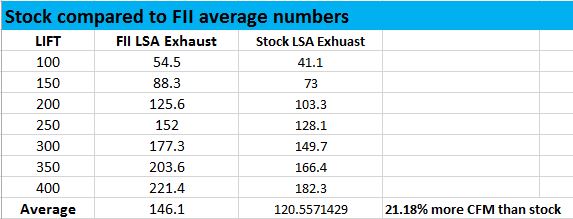

We’ve actually done this flow comparison above a favor REALLY look at the exhaust flow numbers from 0.100″ to 0.400″ we will chart that for you now below:

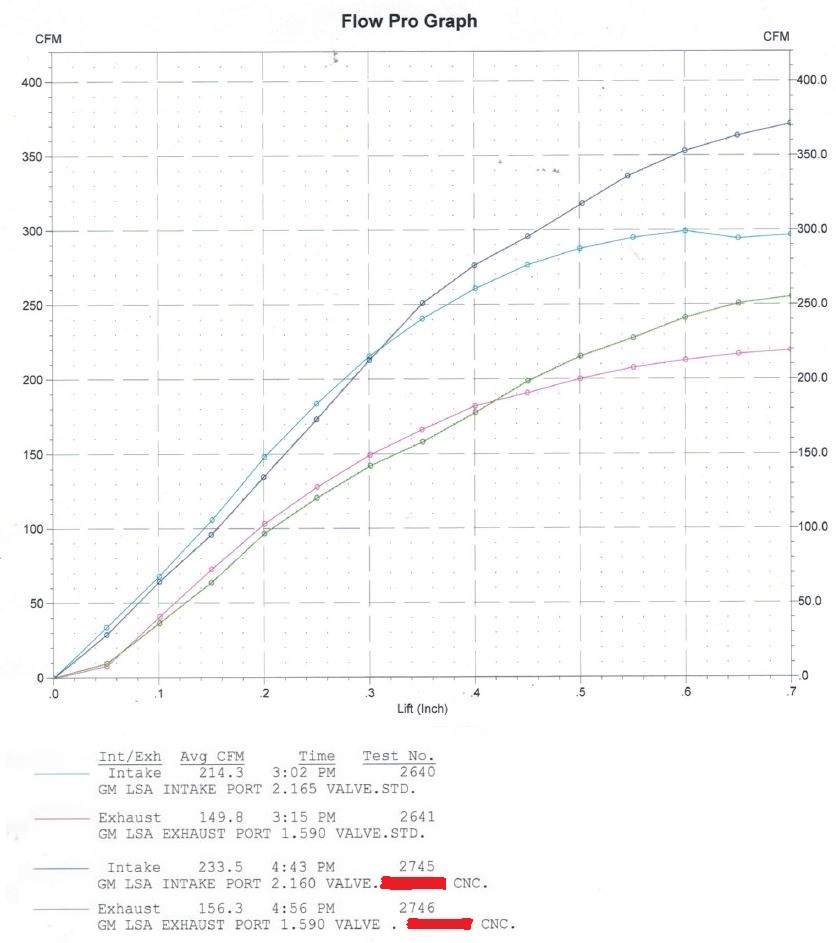

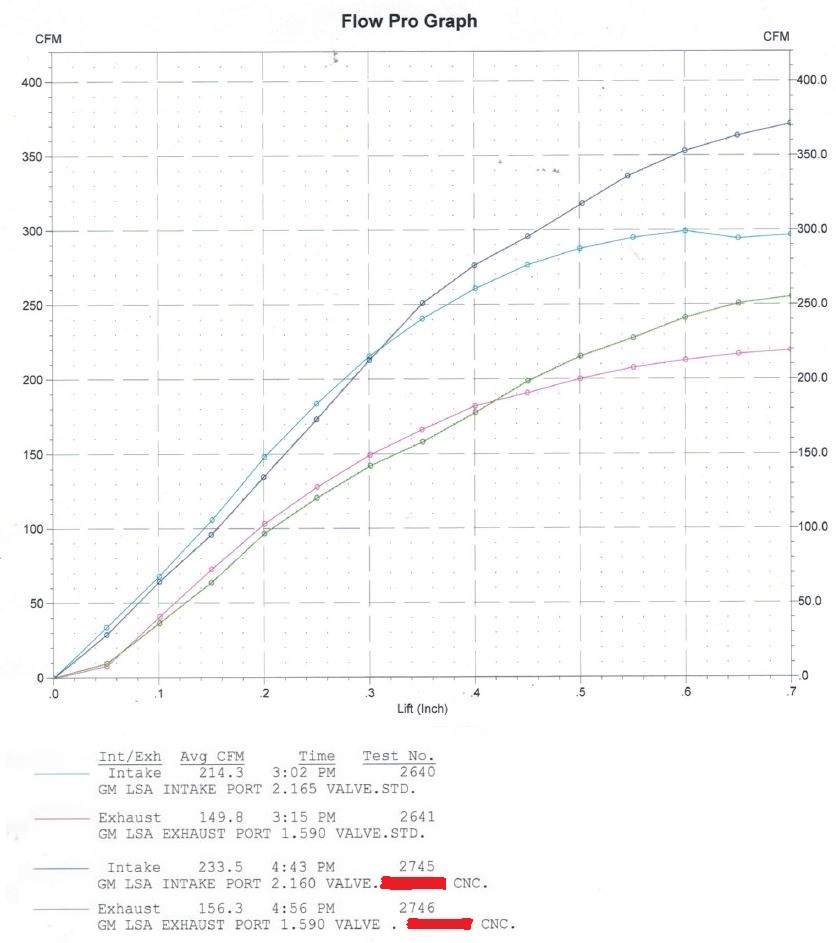

Actual flow graph for this comparison here:

In this graph we can see that this head actually flows less CFM and less velocity up to 0.325″ lift on the intake and 0.430″ thou lift on the exhaust compared to stock, that’s not good.

Since most people run a camshaft with a peak valve lift usually between 0.500″ and 0.650″ half of the camshaft lift flow and velocity has been lost. Those losses of CFM and velocity are then made up for at the peak lift figures….a robbing Peter to pay Paul type of scenario, however as you know peak figures are not as important as low to mid lift figures since we do not spend much time at peak lift. The interesting thing with this heads is they are advertised to flow over 380CFM which is a great marketing tactic… but that’s only at 0.900″ lift which nobody runs other than full blown drag cars and if you did run that kind of lift it wouldn’t be with an LS3 cast factory head.

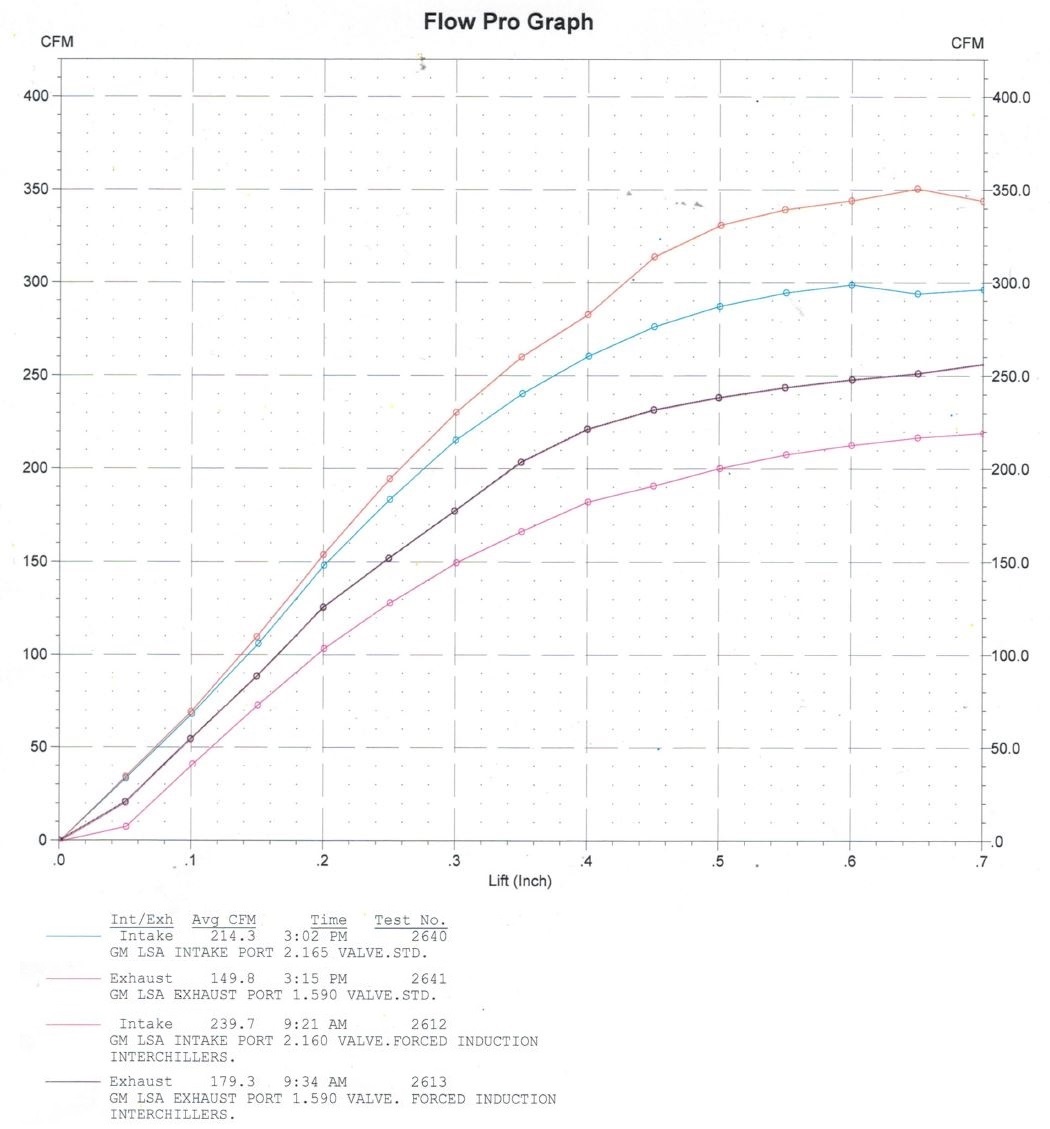

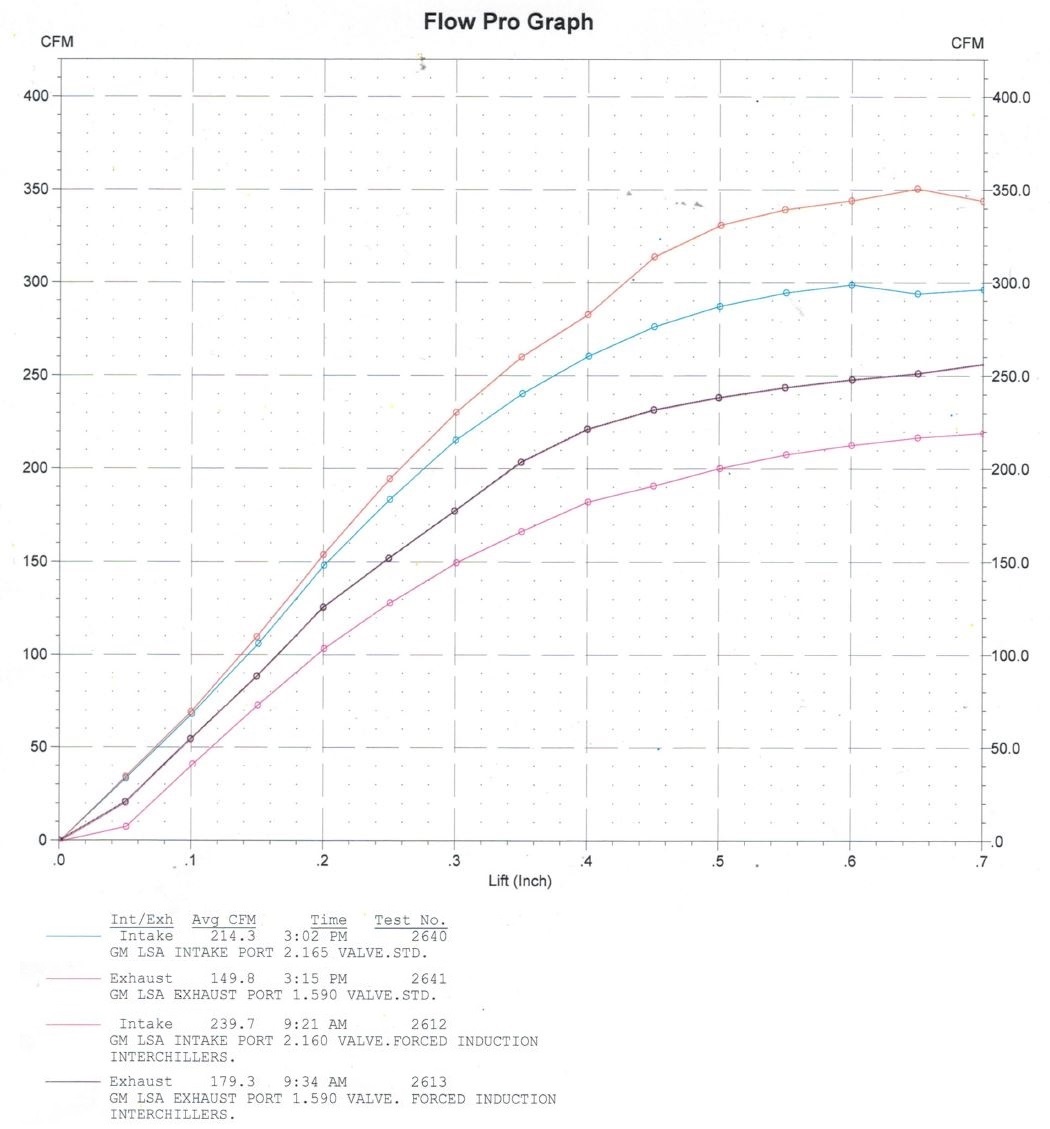

Here we have CFM break points, average CFM at the bottom and the percentage gain from our FII CNC ported head:

Just to keep it all fair we will do the same for the exhaust on our head from 0.100″ to 0.400″

Actual flow graph for this comparison here:

On the FII head vs the stock LSA we can see that intake flow exceeds the stock LSA head from low lift, right up to peak lift flowing more and more all the way up to 0.650″ lift, showing that this head was designed for camshafts up to 0.650thou lift.

On the exhaust side we can see particular attention has been paid here since being made for a supercharged application exhaust evacuation is critical, the average flow through the curve there of the exhaust is extremely good.

What did the data tell us?

- So far we have learned the following:

- The bad CNC heads intake flows on average from 0.050″ to 0.500″ 1.7% more than stock

- The stock heads exhaust flows on average from 0.050″ to 0.550″ 0.285% more than the CNC head!

- The stock heads exhaust flows on average from 0.100″ to 0.400″ 6.08% more than the CNC head!

- The FII heads intake flows on average from 0.050″ to 0.500″ 8.9% more than stock

- The FII heads exhaust flows on average from 0.050″ to 0.550″ 21.12% more than stock

- The FII heads exhaust flows on average from 0.100″ to 0.400″ 21.18% more than stock

You can see where this is going now right?

Our goal to creating HP/TQ on the intake is to get air into the engine (oxygen) combine that air with fuel, ignite the air and fuel and create pressure (power) to drive the piston down the cylinder bore as hard as we possibly can, the more air (oxygen) we can get into the engine the more power we are able to create.

Now on the exhaust side our goal is to clear the cylinder of gasses as fast as possible so that on the next intake stroke we have:

1. More cylinder volume (space) to fill with air

2. A cleaner cylinder volume (space)

We want the cylinder to be as empty as possible so that when the next intake event occurs again we can fill the cylinder with lots of clean fresh air vs air and trapped gasses. So the more we can essentially CLEAN the exhaust gasses from the engine the more air we can put into the cylinder and the more power we can make.

Now next time you get your heads ported, don’t ask for ported heads, ask about the heads, just because your friend said this guy is great doesn’t mean anything.

Your intake/exhaust port and valves represent the LARGEST flow restriction in your engine, the bottleneck, where the ports neck down to the smallest point in the engine, just before and right after the air goes in and out of the engine, improving air flow at this point is the most critical part of making HP/TQ. You can have all the flow in the world prior to the intake and exhaust valve but that air still has to cram itself through that tiny little hole and around the valves.

Just because the heads are “ported” as you can see doesn’t mean it is better. Airflow is everything to an engine, make it work correctly and you can make plenty of power from it.

LSA/LS3 cylinder head shootout here if you want to compare more heads: https://fiinterchillers.com/lsa-ls3-cylinder-head-shoot-out/

You should also be aware of head porters shaving 20thou or more off the deck of your heads, they do this to increase the compression ratio of the engine, which can help create more HP, however your deck is thick from factory to handle/withstand cylinder pressure to hold the head down and stop it from lifting, this is why aftermarket heads have even thicker decks than the factory to deal with the increased pressure, you want that meat there to keep the head on the engine and not have it lift the head on you. Your friend might say mines shaved and it’s fine, but he probably isn’t ever going to achieve the same HP as the educated person looking into heads and camshafts for their combo looking to make the most efficient engine possible.

Lastly let’s briefly touch on this and maybe we can discuss it further in another tech article, when you have a bad cylinder head you over cam the engine, you do this to make up for the fact that your heads are not that great, you have a longer duration to try and get more air into the cylinder, band aiding to help the engine, once your heads are good you can go smaller on the duration of the camshaft. Bigger is better right? no it’s not once you fill the cylinder with air, it’s now full to capacity leaving the intake valve open any longer than needed is wasting time and energy (time and energy which could be used for the process of combustion) The quicker we can fill the engine with air the earlier we can close the intake valve the longer you can burn the air and fuel creating even more HP by having a longer combustion phase, pushing down on the piston for a longer period of time.

This is why it’s important to NOT pick a camshaft from a catalog and also why it is important to flow bench your heads, once you know how the heads flow you can work out your desired camshaft to make optimal power, or at least your engine builder can for you. Or even camshaft data programs that you can download online.

Without head flow data you cannot pick a camshaft, you would simply be guessing. There is no such thing as a magic camshaft, there is only the right camshaft to suit the engine combination. If you get your combo right you will make lots of power (combo being from intake air filter to muffler tip).